That's exactly what happened right as I was getting ready to animate another shot. Ahh well at least he didn't complain much. I'm sure there would have been a lot more screaming, crying and excessive bleeding if he was any less of an actor, but being the dedicated and talented young artist that he is, he took it like a champ.

Here's a photo of the fracture. Right as I looked at it I realized what caused the premature break. I remember accidentally scrapping this piece of aluminum wire with a pair of steel pliers when fabricating this particular armature. Using anything metal to bend or shape any aluminum armature is something that should be done with care due to the possibility that it might kink the wire thus making it more susceptible to breakage in that area while animating. I usually use my hands as much as I can but on this particular day I was feeling invincible... invincibly stupid. There are times when I do need to use pliers to make tight bends but when these instances occur I usually like to wrap the wire in tape or thick cloth of some kind to prevent any unnecessary damage.

Here's the new armature with the tie down screws attached and placed inside the mold for registration right before foaming.

The armature after it's been foamed, baked and the excess foam flashing trimmed off.

After the edges have been seemed, imperfections in the foam repaired and final paint applied.

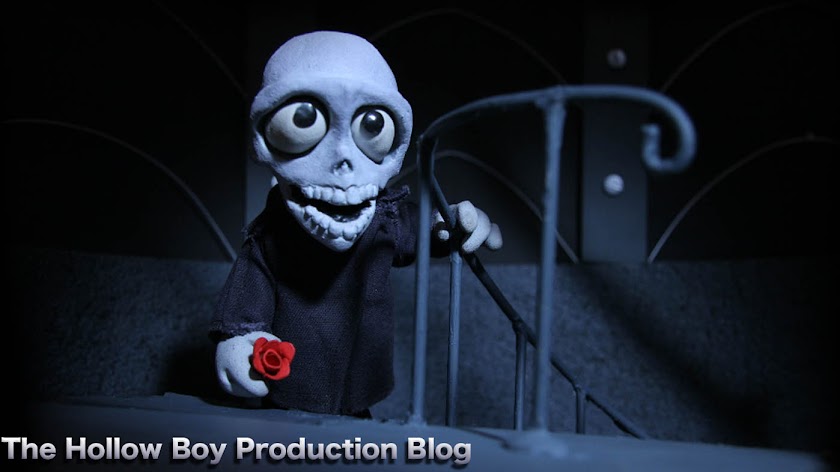

It's party time

There are a lot of options to consider when thinking about what material you want to use to create your characters. I ended up going the foam latex route because I've always liked the way foam latex puppets handled, moved and looked. I've been using a GM foam latex kit and have been very happy with the results. It's also a brand that used by a lot of professionals so you can't go wrong. I get most of my foam and puppet fabrication supplies from Frends Beauty Supply in North Hollywood. They have a lot of great stuff there for your foam and mold making needs.

I don't mean to simplify the whole mold making and puppet foaming step because it is anything but. It's a very time consuming and detailed process that takes a couple of tries to get right, especially when it comes to foaming a character. Here are some excellent links to help you on your way to making a foam latex puppet:

Do It Yourself! Foam Latex Puppetmaking 101 : A great tutorial DVD that shows you all you need to know about the foam latex process. Another plus about purchasing this DVD is that creator, Kathi Zung, has been generous enough to offer unlimited tech support. I have the DVD and on many occasions have contacted Kathi with questions about the process and she has always been more than happy to help.

Stop-Motion Magazine Tutorials : These guys are great! They've posted tutorials about the process on you tube, and the best thing about it is that they are free! They also have free bi-monthly magazines about everything stop-motion. Check them out here along with some other free stuff they offer: stopmotionmagazine.com

After becoming familiar with the foam latex process you'll need a few more things. One is an electric mixer and the other is a scale to measure your ingredients. Now I've seen people use some pretty fancy, and by fancy I mean expensive, equipment. But since I'm not mass producing my puppets for a series or making more than a couple every few months, I can make due by using these relatively inexpensive tools. The mixer is a regular Oster hand mixer and the scale is a Chefmaid plastic scale which I both bought at Target for under $30.

You are also going to need an oven since everything you use, including the electric mixer, SHOULD ONLY BE USED FOR FOAMING NOT FOR FOOD PREPARATION. I bought this Hamilton Beach electric oven at Costco a while back for about $60 and it works great. Or if your feeling crafty you can make one yourself: Foam Latex Oven Build

-Alfonso